Favorite Info About How To Build A Anaerobic Digester

The most common application of the anaerobic digestion technology in.

How to build a anaerobic digester. In some digester designs the stage 1 process is carried out in a separate reactor. A dozen digesters in two decades. Make sure you have enough land.

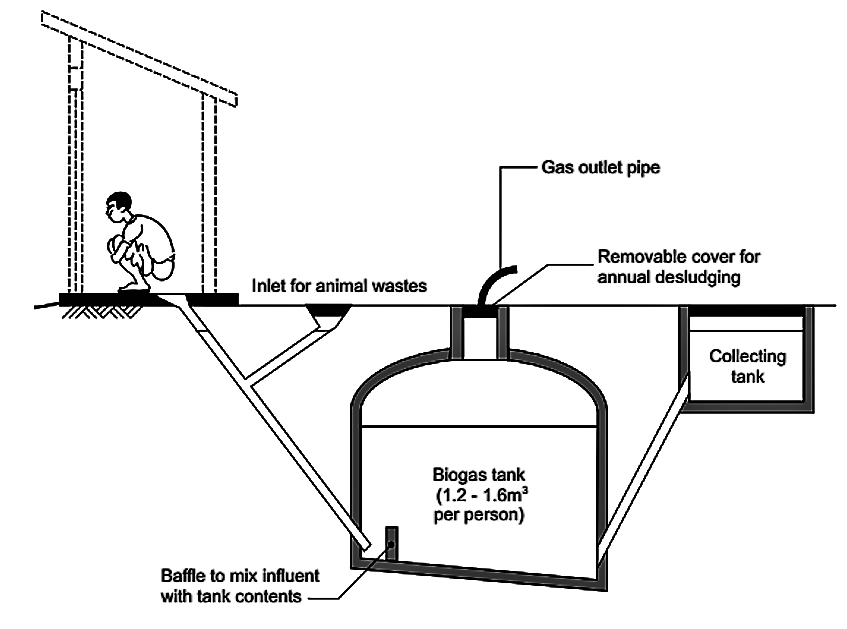

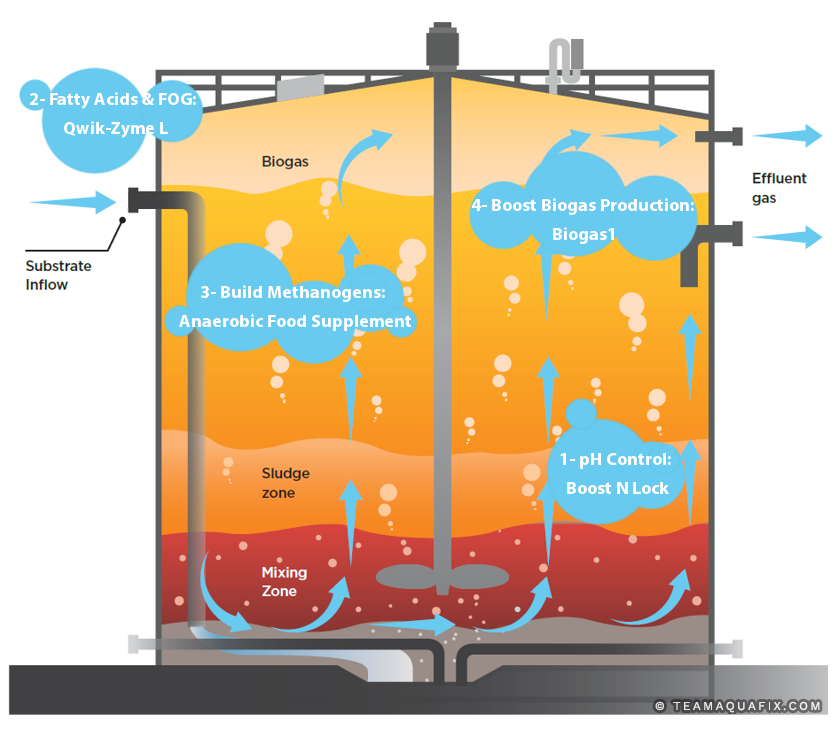

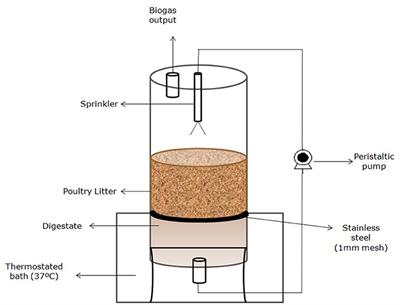

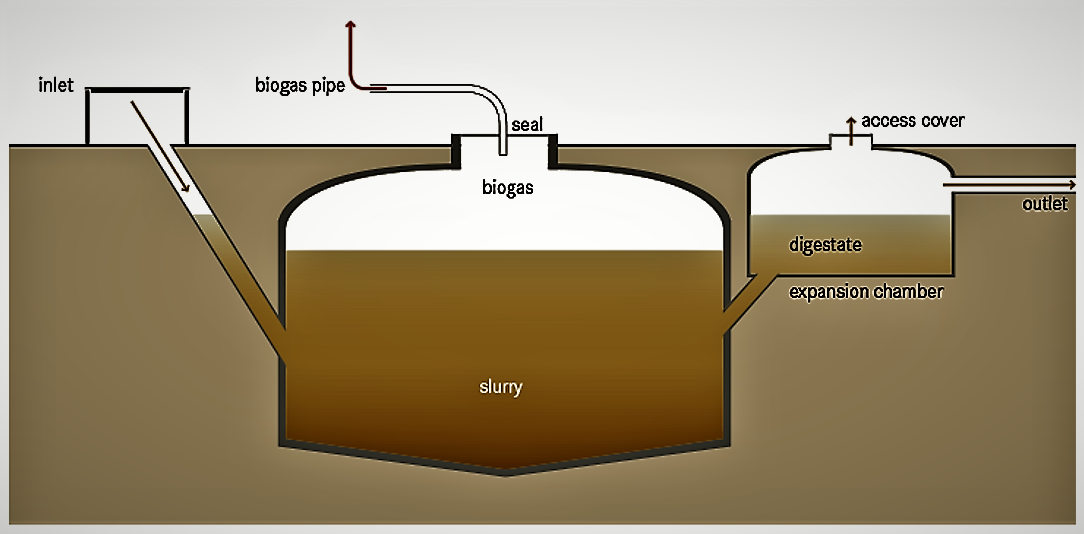

The entire anaerobic digestion system requires integrated tanks, mixers, covers, and heating systems. Anaerobic digestion is a process where biogas is generated from organic substance in the absence of oxygen. Will it work on your farm?

Anaerobic digester manufacturer in china center enamel is china's leading manufacturer of anaerobic digesters and the first company to build anaerobic digester in china. We will need biomass to make an anaerobic digester. Specialty blends of micronutrients, microbial cultures, microbial growth enhancers and neutralizing agents when.

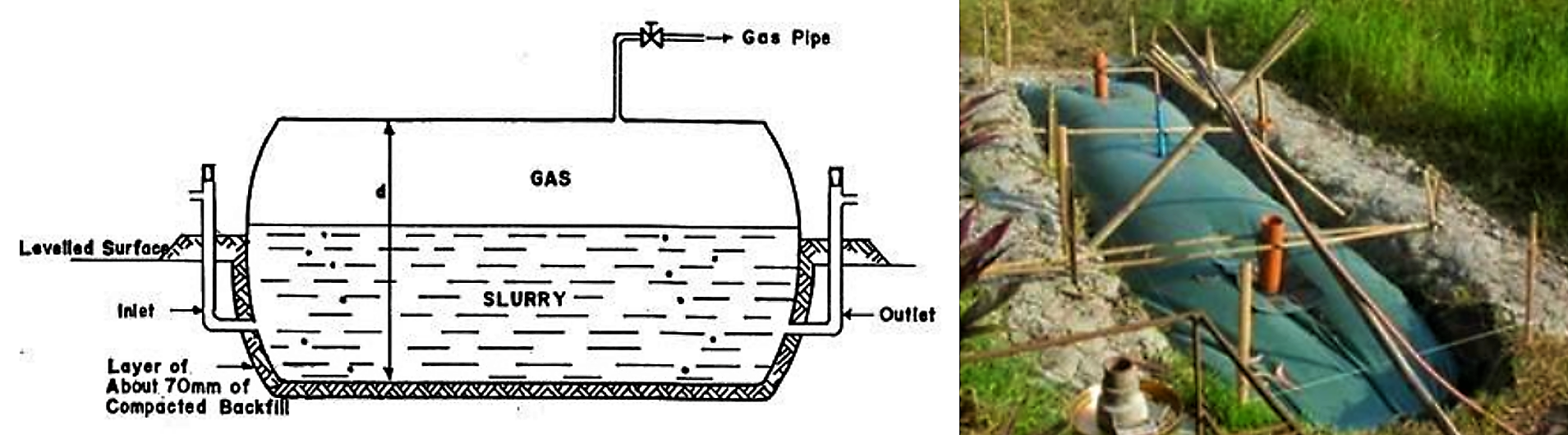

All three are plastic (hdpe), and all. Figure 1the basic layout of the digester and gas collector to fit on the area of a standard pallet. There will be a folder.

Once you have determined that anaerobic digestion is technically feasible ( step 1) and have measured your methane generation potential ( step 2 ), it is important to consider whether the. Regenis has built more manure digesters than anyone in the western united states. The first thing 1 had to do was to build a platform for the digester to sit on.

With a combined total of 120 years in service, 30 billion cubic feet of. For example, cow manure, grass clipping with soil or any other waste, cow manure serves a starter to produce biogas. Hello everyone from around the world, the following video will show you a step by step guide on how to build your own biogas digester.